|

Ningguo BST Thermal Protection Products Co.,Ltd

|

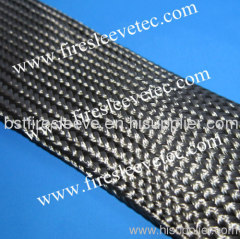

Acrylic Saturated Heat Treated Fiberglass sleeve

| Price: | 1.0~20.0 USD |

| Payment Terms: | T/T,WU;paypal |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Acrylic Saturated Heat Treated Fiberglass sleeve is an expandable braided glass fiber sleevecapable of operating at a continuous temperature of 1000°F

1000°F / 538°C Continuous Exposure: HigherIntermittent

Acrylic Saturated Heat Treated Fiberglass sleeve

Constructed from smooth glass fiber yarn, braided at high yield angles toallow for approx: 25% expansion and contraction.

Heavy wall braided glass fiber sleeve

Acrylic Saturated Heat Treated Fiberglass sleeve is an expandable braided glass fiber sleevecapable of operating at a continuous temperature of 1000°F (538°C).

Acrylic Saturated Heat Treated Fiberglass sleeve is an expandable braided glass fiber sleevecapable of operating at a continuous temperature of 1000°F (538°C).

Designed to expand and contract by approximately 25% of its nominal size, thesmooth glass fiber yarn is heat cleaned and coated with an acrylic saturant toeliminate loose fibers, enhance handling characteristics, and improve abrasionresistance. The acrylic saturant begins to decompose around 400°F (204°C), butwith no effect on the thermal performance of the sleeve.

Expandability creates custom size range

Due to its widerange of expansion and contraction, Fiberglass Braided Thermo Sleeve isavailable in just four nominal sizes that cover a complete range of diametersfrom 6mm up to 130mm.

Due to its widerange of expansion and contraction, Fiberglass Braided Thermo Sleeve isavailable in just four nominal sizes that cover a complete range of diametersfrom 6mm up to 130mm.

Always wear safety glasses, dust mask, gloves and long sleeves are recommended when handling this product

Proudly Made By BST Thermal Protection Products Co.,Ltd

Proudly Made By BST Thermal Protection Products Co.,Ltd

Acrylic Saturated Heat Treated Fiberglass sleeve - QuickFacts | |

|---|---|

Continuous operating temp: | 1000°F (538°C) |

Max short term exposure: | 1300°F (705°C) |

Flame resistance: | Very good |

Abrasion resistance: | Very good |

Flexibility: | Outstanding |

Expandability: | Outstanding |

Water and oil resistance: | Moderate |

Related Search

Fiberglass Insulating Sleeve

Heat Shrink Sleeve

Heat Shrinkable Sleeve

Heat Sleeve Bushing

Saturated Polyester Resin

Sleeve

More>>