|

Ningguo BST Thermal Protection Products Co.,Ltd

|

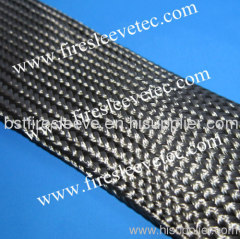

Heat Treated and Saturated Fiberglass Sleeving

| Price: | 0.1~30.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU;PAYPAL |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Heat Treated and Saturated Fiberglass Sleeving is comprised of tightly wovenelectrical grade fiberglass braid that has been heat-cleaned and saturated

1200°F / 648°C Continuous Exposure: Higher Intermittent

Heat Treated and Saturated Fiberglass Sleeving

Heat Treated and Saturated Fiberglass Sleeving is comprised of tightly wovenelectrical grade fiberglass braid that has been heat-cleaned and saturated withacrylic resin to resist fraying of cut ends.

Heat Treated and Saturated Fiberglass Sleeving provides space factor thermaland electrical insulation properties at temperatures up to 650ºC, withcontinuous operation at 450ºC.

Heat Treated and Saturated Fiberglass Sleeving is used in high temperature,low voltageup to 300V applications such as toasters, coffee makers, and othersmall heating appliances. Its flexibility and expandability allows for use overirregular shapes. It is also used for thermal and cut-through protection inautomotive wire harness assemblies as well as track, stage and other types oflighting devices.

Thermal Class 240°C

UL VW-1

Dielectric Grade C3 (no dielectricguaranteed)

Resists solvents and engine fluids

1:1.25 expansionratio

Lightweight and flexible

Compliant with the European Union'sRestrictions on the use of Hazardous Substances (RoHS) Directive

Cuts easilywith scissors

High abrasion resistance

Contains no asbestos

Noncorrosive to metals

Excellent resistance to moisture, fungus and chemicalattack

Continuous operating temperature -94°F to 1,200°F

UL VW-1

Dielectric Grade C3 (no dielectricguaranteed)

Resists solvents and engine fluids

1:1.25 expansionratio

Lightweight and flexible

Compliant with the European Union'sRestrictions on the use of Hazardous Substances (RoHS) Directive

Cuts easilywith scissors

High abrasion resistance

Contains no asbestos

Noncorrosive to metals

Excellent resistance to moisture, fungus and chemicalattack

Continuous operating temperature -94°F to 1,200°F

Always wear safety glasses, dust mask, gloves and long sleevesare recommended when handling this product

Proudly Made By BST Thermal Protection Products Co.,Ltd

Related Search

Fiberglass Sleeving

Silicone Fiberglass Sleeving

Flexible Silicone Fiberglass Sleeving

Pvc Fiberglass Sleeving

Fiberglass Sleeving Tube

Saturated Polyester Resin

More>>