|

Ningguo BST Thermal Protection Products Co.,Ltd

|

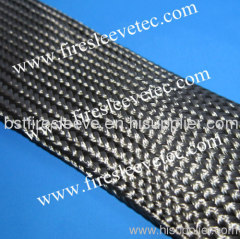

Silicone coated fiberglass fire sleeving

| Price: | 1.8~50.0 USD |

| Payment Terms: | T/T,WU;PAYPAL |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

silicone coated fiberglass fire sleeving is made by fiberglass and silicone.We can make silicone coated fiberglass fire sleeving size from 4mm to 130m

500°F/260°C Continuous Exposure: HigherIntermittent

Silicone coated fiberglass fire sleeving

Thicker, denser inner glass fiber than our Industrial grade Firesleeve giveshigher insulation values, increased strength and enhanced abrasionresistance.

Sheds splash immediately

Silicone coated fiberglass firesleeving withstands repeated exposures to molten steel, molten aluminum andmolten glass up to 3000°F (1650°C). The heavy coating of our proprietaryfiresleeve iron oxide red silicone rubber compound sheds molten metal splashimmediately, so very little heat transfer occurs.

Silicone coated fiberglass firesleeving withstands repeated exposures to molten steel, molten aluminum andmolten glass up to 3000°F (1650°C). The heavy coating of our proprietaryfiresleeve iron oxide red silicone rubber compound sheds molten metal splashimmediately, so very little heat transfer occurs.

Withstands intense radiant heat and flame

Silicone coatedfiberglass fire sleeving will withstand continuous exposure to 500° F (260°C);up to 2000°F (1090°C) for 15-20 minutes; and up to 3000°F (1650°C) for 15-30seconds. When exposed to flames, the silicone rubber transforms into a crust,creating a protective SiO2 refractory layer.

Silicone coatedfiberglass fire sleeving will withstand continuous exposure to 500° F (260°C);up to 2000°F (1090°C) for 15-20 minutes; and up to 3000°F (1650°C) for 15-30seconds. When exposed to flames, the silicone rubber transforms into a crust,creating a protective SiO2 refractory layer.

Silicone coated fiberglass fire sleeving is constructed from high bulk glassfiber braided sleeve. Excellent modulus of elasticity makes it an ideal choicefor bundling hoses, tubes and cables in a variety of hostile high heatenvironments.

Custom colours are available by special order.

Always wear safety glasses, dust mask, gloves and long sleeves are recommended when handling this product

Proudly Made By BST Thermal Protection Products Co.,Ltd

Proudly Made By BST Thermal Protection Products Co.,Ltd

Silicone coated fiberglass fire sleeving - QUICKFACTS | |

|---|---|

Continuous operating temp: | 500°F (260°C) |

Max short term exposure: | 3000°F (1650°C) |

Molten splash resistance: | Outstanding |

Flame resistance: | Very good |

Abrasion resistance: | Very good |

Durability: | Outstanding |

Flexibility: | Outstanding |

Water and oil resistance | Outstanding |

Related Search

Silicone Fiberglass Sleeving

Flexible Silicone Fiberglass Sleeving

Silicone Coated Fiberglass Fabric

Silicone Coated Fiberglass

Fiberglass Sleeving

Pvc Fiberglass Sleeving

More>>