|

Ningguo BST Thermal Protection Products Co.,Ltd

|

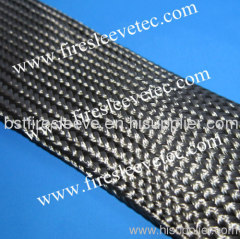

Fiberglass braided silicone exhaust sleeve

| Price: | 1.8~50.0 USD |

| Payment Terms: | T/T,WU;PAYPAL |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

Fiberglass braided silicone exhaust sleeve is made by fiberglass and silicone. We own fire sleeve patent. We can make fire sleeve size from 4mm to 130

500°F/260°C Continuous Exposure: HigherIntermittent

Fiberglass braided silicone exhaust sleeve

Braided high bulk glass fiber sleeve can withstand repeated exposures tomolten steel, molten aluminum and molten glass up to 3000°F (1650°C).

Sheds splash immediately

Fiberglass braided silicone exhaust sleeve withstands repeated exposures to molten steel, moltenaluminum and molten glass up to 3000°F (1650°C). The heavy coating of ourproprietary iron oxide red silicone rubber compound sheds molten metal splashimmediately, so very little heat transfer occurs.

Fiberglass braided silicone exhaust sleeve withstands repeated exposures to molten steel, moltenaluminum and molten glass up to 3000°F (1650°C). The heavy coating of ourproprietary iron oxide red silicone rubber compound sheds molten metal splashimmediately, so very little heat transfer occurs.

Withstands intense radiant heat and flame

Fiberglass braided silicone exhaust sleeve will withstand continuous exposure to500° F (260°C); up to 2000°F (1090°C) for 15-20 minutes; and up to 3000°F(1650°C) for 15-30 seconds. When exposed to flame, the silicone rubbertransforms into a crust, creating a protective SiO2 refractory layer.

Fiberglass braided silicone exhaust sleeve will withstand continuous exposure to500° F (260°C); up to 2000°F (1090°C) for 15-20 minutes; and up to 3000°F(1650°C) for 15-30 seconds. When exposed to flame, the silicone rubbertransforms into a crust, creating a protective SiO2 refractory layer.

BST Industrial Grade Better Than Pyrojacket Fire Sleeve is constructed fromhigh bulk glass fiber braided sleeve. Excellent modulus of elasticity makes itan excellent choice for bundling hoses, tubes and cables in a variety of hostileenvironments.

Protect your personnel and cut your energy loss

BSTIndustrial Grade Better Than Pyrojacket Fire Sleeve is insulation propertiesprovide personnel with effective protection against burns from hot hoses andflexible steam lines, while reducing heat energy losses.

BSTIndustrial Grade Better Than Pyrojacket Fire Sleeve is insulation propertiesprovide personnel with effective protection against burns from hot hoses andflexible steam lines, while reducing heat energy losses.

Always wear safety glasses, dust mask, gloves and long sleeves are recommended when handling this product

Proudly Made By BST Thermal Protection Products Co.,Ltd

Proudly Made By BST Thermal Protection Products Co.,Ltd

Fiberglass braided silicone exhaust sleeve -Quick Facts | |

|---|---|

Custom colours available by specialorder. | |

Continuous operating temp: | 500°F (260°C) |

Max short term exposure: | 3000°F (1650°C) |

Molten splash resistance: | Outstanding |

Flame resistance: | Very good |

Abrasion resistance: | Very good |

Flexibility: | Outstanding |

Water and oil resistance: | Outstanding |

Related Search

Fiberglass Braided Packing

Fiberglass Braided Ropes

Braided Fiberglass Ropes

Silicone Fiberglass

Fiberglass Insulating Sleeve

Silicone Coated Fiberglass Fabric

More>>